BICYCLE HELMETS REINVENTED

Day to day, skilled engineers go through various enhanced tests to meet the needs of valued customers. In order to achieve the highest level of performance, various stages of aerodynamic tests are performed in HJC’s own wind tunnel test lab in parallel with live testing situations.

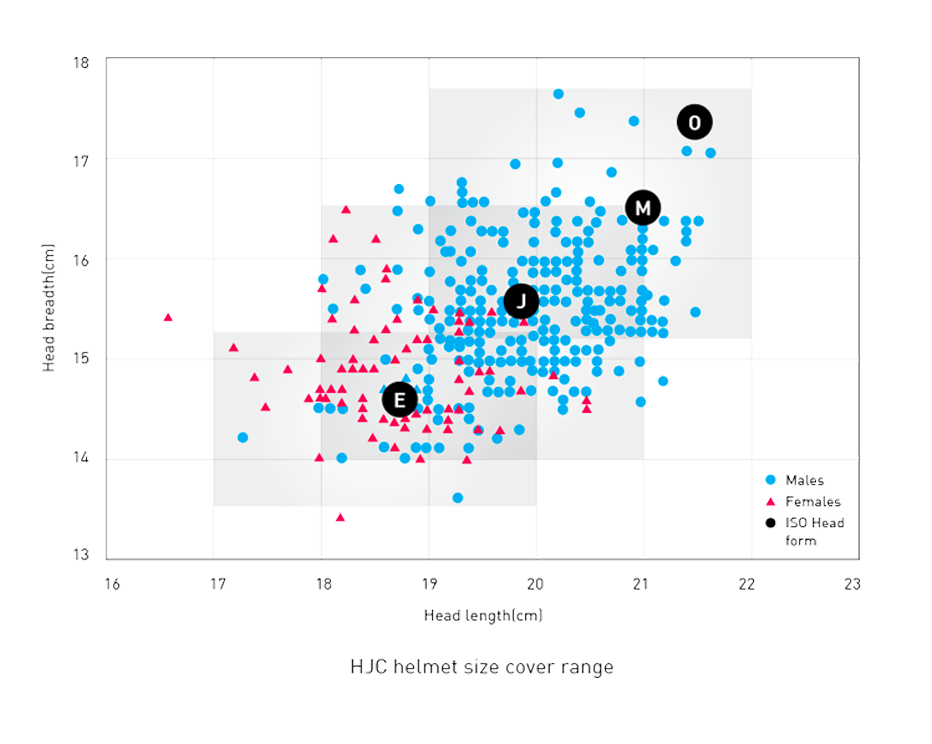

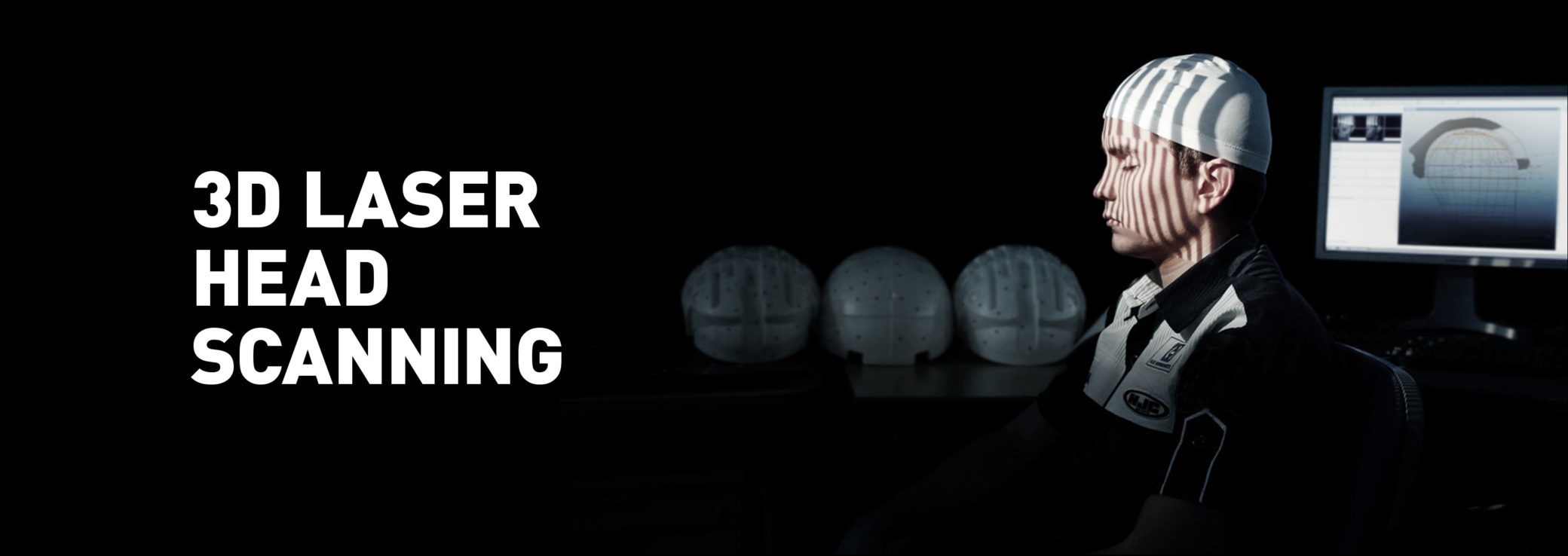

Comfort and fitting are an integral part of HJC’s helmets, and HJC helmets are designed and engineered around actual human laser-scanned profiles for precision fitting. HJC’s in-house test labs are facilitated with advanced test equipment to achieve optimal levels of aerodynamics, safety and performance.

Test lab HJC wind tunnel

HJC helmets are tested in laboratory as well as in “real-life” to meet the highest quality standards. HJC is one of very few helmet companies equipped with its own state of the art wind tunnel laboratory to test aerodynamics, ventilation, noise, and more. From technical development of motorcycle race technology to high-end road cycle helmets, the HJC wind tunnel test lab measures all the relevant forces in a variety of riding conditions to improve the performance of HJC Helmets.

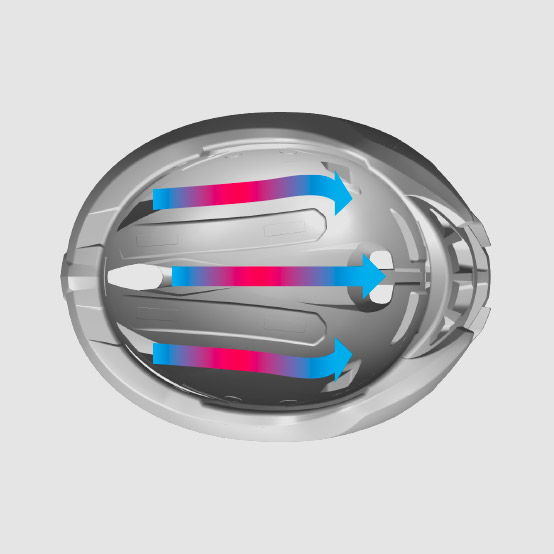

Advanced Ventilation System

In order to achieve maximum ventilation, a technical adaptation of Bernoulli’s principle is applied to HJC’s aerodynamically enhanced models. In motion, the rate of surface flow generally increases as it progresses towards the rear of the helmet. Through pressure differences, cool air from the frontal intake is extracted through the rear vent for internal heat dissipation, giving the cyclist optimum ventilation while riding.

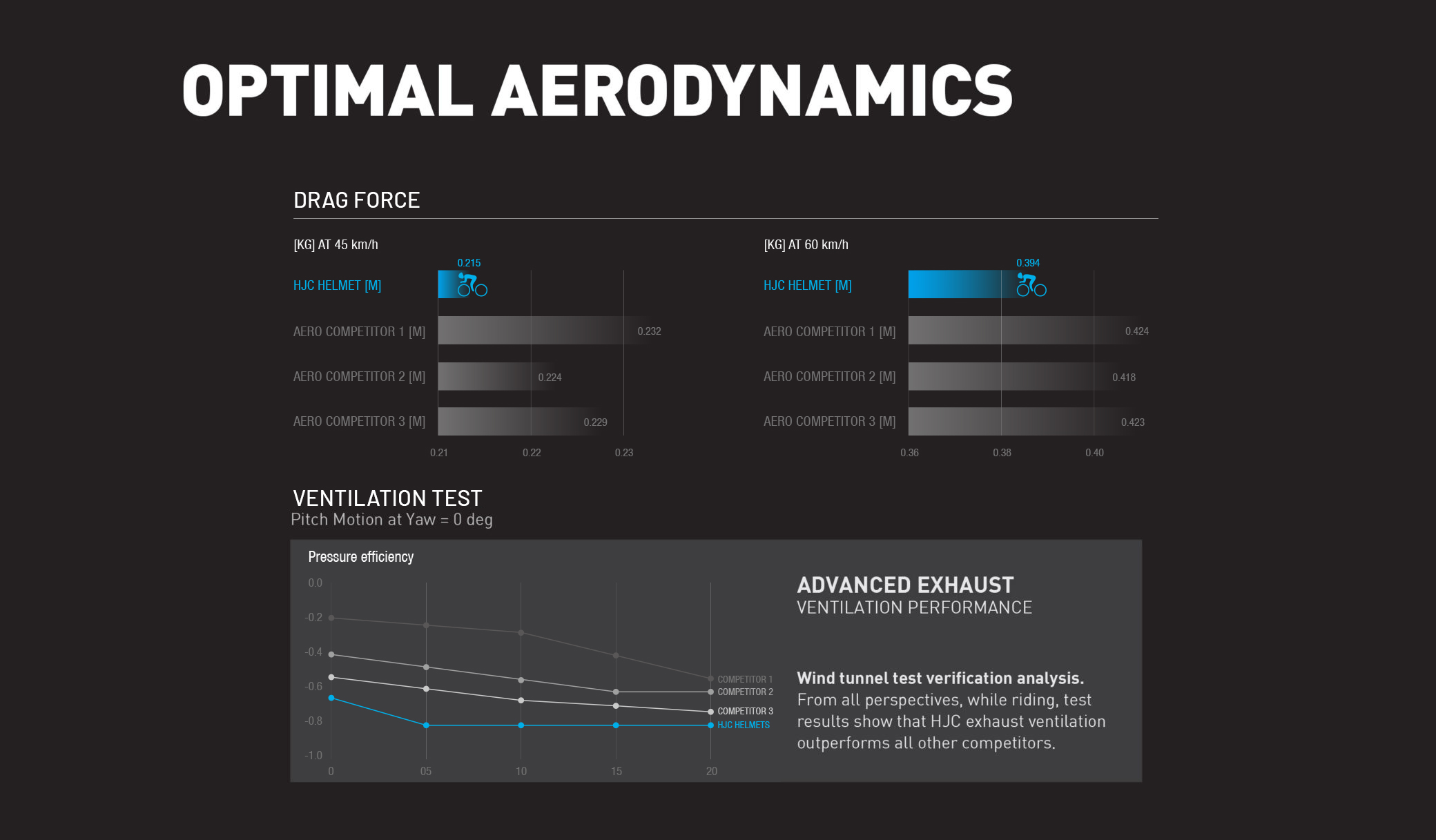

Aerodynamic design

Coming from MotoGP race-helmet design experience, HJC designers and engineers have become experts in aerodynamics and wind ventilated helmets. Aero helmets, as the word implies, are more aerodynamic than the conventional racing bike helmet, but with compromised ventilation performance. With HJC Helmets, this compromise is very much reduced. HJC offers probably the best ventilated semi-aero helmet on the market.

Comfort & safety

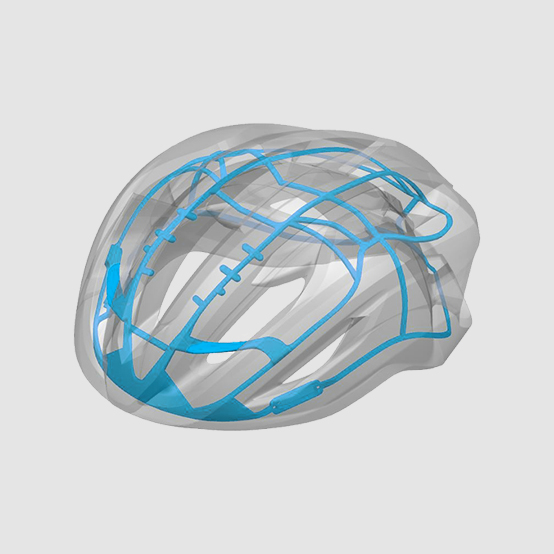

Internal Reinforcement Structure

HJC helmets are reinforced with an internal frame integrated into the EPS. The skeletal frame not only holds the helmet in one piece, but also makes it stronger and more resistant to protect your head in the event of an impact.

Advanced Air Channel System

A certain amount of air passes through the front air-intake port, then circulates inside the helmet and finally exits through the exhaust port. This results in increased internal air flow to cool the head and evacuate heat.

In-Mold Construction

The In-mold construction method consists of bonding the EPS layer together with the outer polycarbonate shell for greater structural strength. This improves the rider’s protection by providing a compact reinforcement and gives the product a perfect finish.

IONIC + Fabric

Made with antimicrobial properties which eliminate bacteria without posing a health risk. These natural elements are integrated into the fabric and do not wash off, making it a long-lasting product.

3D Laser Scan Precision Engineering

The heads of a large sample of people were scanned and analyzed to determine the ideal helmet shape. Indeed, these data allowed engineers to compare a variety of head sizes and shapes from a wide range of genres and ethnic groups to obtain a better fit and optimal comfort in 3 helmet sizes.